Michel Faber liked to have a glass of rum after balancing the day’s ledgers. The shop doors had long been locked and his office, a tidy nook behind a wall of paned merchandise cabinets, was where he sipped Rhum Agricole Martinique. The rum was a treat, reserved for when he helmed the country’s flagship general store near our family home on the salty, bustling peninsula of Conakry, Guinea.

It was the 1930s, and rhum agricole, soap, tinned milk, pâté, bolts of fabric, casks of wine, watches, medicines, stationery, nails, gasoline, candles, tobacco, sugar, biscuits, margarine, and more arrived by boat for distribution to the 12 stores and factories throughout Guinea that my SuSu grandpère Michel managed for his colonial employers, Marseilles-based Compagnie française de l’Afrique occidentale (CFAO).

CFAO ships deposited goods produced and packaged in France (la Métropole and its colonies). Then, into those same hulls went Guinea’s bananas, rubber, leather, wood, pepper, ivory, coffee, gold, and the oily seeds of sesame, peanut, and palm (CFAO 1900:26). Of this shifting assemblage floating back and forth across the Atlantic Ocean, palm oil and palm kernel oil stand out for having, quite literally, greased the wheels of England’s Industrial Revolution.

As historian Martin Lynn explains in Commerce and Economic Change in West Africa, palm oil was used in the manufacture of Europe’s (and Britain’s) soap and candles, in textile trades, and as a lubricant for railroads and industrial machinery (Lynn 2002:3, 46). But its most interesting use, in my view, was as an ingredient in tinning—the process of thinly coating sheets of iron or steel with tin to prevent rusting. This process accelerated one of the most transformative food access innovations: tin cans. Preserving foodstuffs in tin meant reliable nourishment well beyond a harvest, thereby addressing a constant challenge faced by our species. Arguably, the availability of tinned food expanded empires and recalibrated human settlement patterns and diets. Meat, fish, fruit, biscuits, vegetables, cigarettes, and sweeteners all have been tinned at one point or another and made available to workers, picnickers, soldiers, and travelers alike.

Palm oil’s role in tinning was inceptive and specific:

After the second bath in sulphuric acid the [metal] sheets remain in water until ready for tinning. Standing in front of the dresser are three men, known as the tinman, the washman, and the riser. They are flanked by several girls, called “branners” and “cleaners.” Into the first pot containing boiling palm oil, the tinman places the sheets one by one and leaves them immersed from one to five minutes in order to clean the surface of all impurities and make it absorbent. Next, he transfers the sheets to the second pot which holds molten tin. They remain immersed from two to five minutes, and their surface forms an amalgam with the tin (Dunbar 1915:10).

The foods preserved in tin cans, in turn, were inserted into regional diets across the globe. I’m thinking here of the great Spam, bean, and evaporated milk diasporas. When we look down grocery store aisles, lined floor-to-ceiling with canned foods, we are seeing the peculiar industrial legacy of West Africa’s great oil palm, Elaies guineensis.

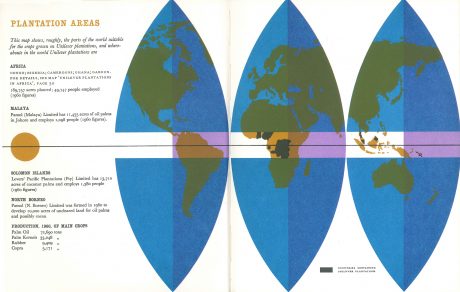

While the oil palm is now found in Southeast Asia and South America, it is indigenous to Africa, flourishing between 7 degrees north and south of the equator with its greatest concentration in West Africa between Sierra Leone and Congo (Lynn 2002:1). One of the most productive of the world’s oil plants, E. guineensis can live for up to 200 years, yielding two crops of fruit annually during its reproductive years.

Pendulous clusters of up to 700 plum-sized fruits teeter at the top of mature oil palm trees, which can grow to 65 feet above ground. Harvesting and milling palm fruit and kernels is tremendously labor intensive. The deftness and daring demonstrated by traditional palm fruit cutters is impressive. Once cut, there are two types of oil extracted from the palm fruit that partially account for its dual role as a food and as an industrial oil. From the fleshy outer pericarp comes the familiar bright orange culinary oil, which, at a cool room temperature, has a consistency of fresh milk pudding. And, from the cocooned inner seed comes palm-kernel oil, a “soft,” highly processed, colorless, translucent oil developed to meet Europe’s (chiefly Britain’s) demand for tin cans, cheap margarine, and cheap soap (Billows and Beckwith 1892:3). Soft palm oil, low in free fatty acids, was perfect in consistency and price for machine lubrication, particularly tin-plate processing.

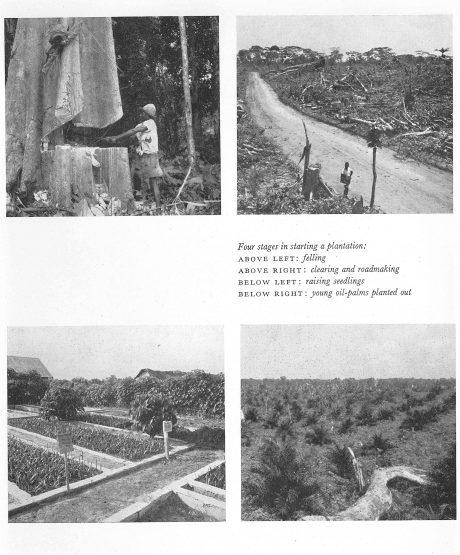

There are traditional, artisanal African methods of milling culinary palm oil from which Europeans’ accelerated production systems were derived, but palm-kernel oil was thoroughly a function of European and British industry (Reader 1961:24). Regardless of processing style, timeliness was key. Once cut, palm fruit rapidly ferments. Cut bunches were quickly collected from fields and delivered to a mill where the fruit was “sterilized” and the pulp separated from the kernels. Kernels were bagged for transport and later processing. The pulp went through various extraction methods until an acceptable grade of culinary or lubricating oil was obtained. The oil was then poured into locally made drums for an impending sea voyage.

All the time that it moonlighted as an industrial tool, palm oil remained an important source of beta-carotenes, vitamin E, and fat in the traditional West African diet. But its use was never limited to the culinary sphere: Africans have long processed palm oil for illumination (lantern fuel) and homeopathic ointments. Available in the wild well before domestication, the entire tree was a resource for building materials (roof thatching, brushes), and its milky sap was the source of palm wine, the beloved (and deplored) African hooch.

But oil is this plant’s gem. Its unctuous nature has taken it from dinner plate in Conakry, Guinea, to tin plate in Liverpool, England, and grocery and canteen shelves the world over. While many of West Africa’s fruits and vegetables have supplied global markets, the oil palm is distinguished by the multiple, consequential functions it has served. As a machine lubricant, it helped build the physical infrastructure of the nineteenth century’s global food system: one that would go on to alter the earth in unprecedented and pernicious ways. Beyond that, as Martin Lynn describes it, there were few nineteenth-century households that did not receive the benefits of the oil palm plant: “…railway carriages greased by palm oil carried members of the British public on their journeys, factory machinery lubricated by palm oil employed them and produced the goods that made their economy ‘the workshop of the world,’ while tins manufactured with palm oil canned their food, and palm kernels fed the cattle that produced the milk they drank with their tea” (Lynn 2002:188).

The Four Stages of Starting a Plantation, from Unilever Plantations by W.R. Reader. London: Unilever Limited, 1961.

This plant, so iconic, so ubiquitous in West Africa’s landscape, is both a food and an industrial ingredient used in transporting other foods. With its sunset palette of oranges, reds, and yellows and what some call a soft aroma of violets or plum cake, palm oil’s place in West African cuisine dates back some 5,000 to 6,000 years, with oil palm fossil pollen identified in Miocene layers in the Niger Delta and archeological evidence of an oil palm trade among third-millennium Egyptians (Andah 1993:87). So essential to the West African diet and identity, palm oil was the oil chosen to provision transatlantic slave ships (Lynn 2002:2).

Let’s return to my grandfather’s shop. After that glass or two of rum, and a bit of camaraderie, Grandpère Michel would return home to his sleeping children and an oil lamp lighting the dining table. His wife, my Grandmère Jeanne, would assemble a plate: perhaps a heaping of warmed rice cradling a large piece of fish from the morning’s catch that had stewed gently in a broth of palm oil, onions, tomatoes and hot peppers, finished with generous splashes of Maggi, imported from the shop. As a little indulgence, since he was on the road quite a bit, the house cook might freshly peel and slice a blackened plantain, perfectly ripe and sweet, and slip the thick rounds into blistering hot, red palm oil until the sides were crisp and caramelized.

After a good night’s rest, Grandpère Michel would rise early, before the sounds of 11 children clanking about the breakfast table and scurrying off to school. He had to make his way to the Port of Conakry to inspect the arriving outre-mer shipments and his own departing cargo to the industries of France and England. But first, he would punch open a can of evaporated milk, pour it into his coffee, and butter a fresh baguette. Standing by the window, he would take his breakfast and look out onto the rising sun that drenched the palm fronds in a silvery hue.